Ufkes Greentec 952 Mega Motor

275-420 HP

55 cm

Approx

8900 kg

Fitted as standard

- GCS control

- Venturi discharge chute can be tilted hydraulically, for easy replacing of the sieve unit

- Stable hydraulic raisable infeedtable, usable in multiple positions

- Pipe, hydraulic up and down, electric chip deflector

- Integrated blowing system which, in combination with Venturi blowing system guarantees a powerfull airstream

- Chassis hydraulic brakes

Options

- Infinitely adjustable flexar reversal fin, saves fuel and reduces noise

- Automatic hydraulically enabled clutch

- Closed infeedchain

- Different crane and crane control options

- Chassis air brakes instead of hydraulic brakes

- Different lighting and support leg options chassis

Versions

- Available with John Deere 275 HP or 420 HP.

- Available with 2 or 4 rollers.

-

2-rollers

4-rollers

- Infeed opening

600 x 1060 mm

600 x 1450 mm

- Feed opening channel

550 x 1060 mm

550 x 1060 mm

- Max. infeed hardwood

Ø 350 mm

Ø 350 mm

- Max. infeed softwood

Ø 520 mm

Ø 520 mm

- Drum

960 x 930 mm

960 x 930 mm

- Upper roll

Ø 500 x 1060 mm

Ø 500 x 1060 mm

- Lower roll

Ø 300 x 1060 mm

Ø 300 x 1060 mm

- Standing Roles

Ø 300 x 610 mm

- Knives

4

4

- Anvil Knives

1

1

- Capacity

150 m3/hour

150 m3/hour

- Size L x B x H

5200 x 2460 x 330

5200 x 2460 x 3300

- Weight

8900 kg

9300 kg

- Parabolic spring suspension

- Emergency stop at both sides and in front at the engine.

- Heavy hydraulic support leg under the drawbar for easy attaching and detaching

- Discharge chute

Equipped with replaceable wear plate.

Hydraulic discharge pipe rotation.

Hydraulic spreader valve adjustment.

Hydraulic discharge pipe adjustment up and down for transport.

Venturi discharge chute can be tilted hydraulically, for easy replacing of the sieve unit. - Screenunit

Knives are easy accessible, under a hinged cover, on the top of the machine.

Simple locking strainer unit by means of 1 pin.

Screenunit made of hardox.

Different screenunits oa. 50 mm- 70 mm and open

- Wood Chipper

Own hydraulic cooling system (using Venturi airflow).

New design rotor housing with wear plate under the shredder drum.

Integrated blowing system which, in combination with Venturi blowing system guarantees a powerfull airstream.

No nonsense machine; chipping at the front, discharge at the back.

No jacks or accelarator needed, which otherwise shatters good woodchips.

This prevents unneccassary wear, saves power and therefore fuel, resulting in higher efficiency.

Greentec drum woodchippers stand for uniform chips with low particulate percentage.

- Drum

4 knives distributed along the drum, with blower blades on both sides of the drum.

Buttom knive placed below cutting knive, easy accessible.

Specially designed anvil knife, small branches are cut at a differente angle, resulting in better chipping quality.

- Infeed

Lowered table for bottom roller providing more space for wood clamp to insert thick logs.

Upper infeed roller on both sides driven by heavy torq engines with embedded oil bearings (low maintenance)

Bottom roller driven by heavy engine with embedded oiled bearings (low maintenance).

- Quality

All machines are manufactured out of premium steel 355 (52-3).

Teeth on infeed rollers are made of hardwearing Hardox steel, guaranteeing aggressive infeed for years.

Discharge chute and bottom beneath the drum equipped with replacable wear plate made of hardwearing Hardox steel.

After sandblasting machines are double powder coated.

Machines are made of durable materials, including bearings, hydraulic valves, engines, pumps and more.

- Maintenance

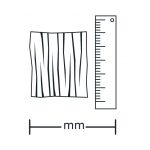

Knives are easy accessible, under a hinged cover, on the top of the machine.

Drum is easily secured for changing knives.

Knives are easy to adjust with supplied ruler.

Anvil knife adjustable, and can be used four times.

Grease nipples are easily accessible.

- GCS control – Greentec Control System

Compact touchscreen control.

Programs for different wood types.

In these programs different parameters are adaptable. Pressure down at top roller, starting and stopping speed of the no stress, either or not reversing of the infeed rollers and infeed speed.

Easy switch to low engine speed to reduce fuel consumption and noise. This gives coarse wood chips with even lower fine percentage.

Chip size and wood type adjustable at any time.

Stopping and if needed short reversing of the infeed responds not only to speed, but also to working pressure of the system.

GCS control box compact design with stainless steel casing.

Vulcanised controllers without moving parts, less chance of error.

In these programs different parameters are adaptable. Pressure down at top roller, starting and stopping speed of the no stress, either or not reversing of the infeed rollers and infeed speed.

Exclusive on Ufkes Greentec machines.

Least possible electronics (relay, cables and more), operational reliability.

Minimum cables on the machine, only Canbus signal with plus and minus.

Minimal chance of errors

Waterproof up to IP67.

5 languages available; Dutch/English/French/German/Polish.